Industrial Tablets for Manufacturing: What They Are and Why You Need One

Industrial tablets for manufacturing are revolutionizing how companies operate. They offer a number of advantages over traditional computers, which is why they’re being adopted in more and more industries. In this guide, we’ll discuss what industrial tablets are, why they’re used in manufacturing, and the features that make them so advantageous. We’ll also explore the trends in industrial tablet technology so you can stay ahead of the curve!

Investing in industrial tablets for manufacturing is a key part of any digital transformation strategy. They are revolutionizing how companies operate by offering several advantages over traditional computers. In this guide, you’ll learn what industrial tablets are and why they’re used in manufacturing. Discover how industrial tablets that have been adopted for the warehouse and factory floors are now being used by managers who oversee plant operations, and monitor production and performance. We’ll also explore the benefits and advantages of industrial tablets and trends in industrial tablet technology so you can stay ahead of the curve.

What are industrial tablets for manufacturing?

Industrial tablets are specialized computer devices that are designed and built for industrial environments. They are purpose-built to withstand the rigors of industrial use, including vibration, dust, extreme temperatures, and drops. They typically have a longer lifespan than consumer tablets or laptops, with many models rated for four or five years of use.

What are the benefits of industrial tablets used in manufacturing?

Industrial tablets offer a number of benefits over traditional computers:

Reliability and durability:

In industrial settings, reliability and durability are paramount. Computers that are not purpose-built for industrial use can’t withstand the rigors of the environment and are likely to break down or fail soon after being deployed. This can lead to lost productivity, as well as increased downtime and repair costs.

Flexibility:

Industrial tablets offer a high degree of flexibility, as they can be used in a variety of settings and for a variety of tasks. They can be deployed on the factory floor or in the warehouse, and can be used by managers, workers, and technicians alike.

Portability:

Industrial tablets are highly portable, which is a major advantage in industrial settings where space is often limited. They can be easily carried from one workstation to another, or taken with you when you move between locations.

Ease of use:

Industrial tablets are designed to be user-friendly, with large icons and menus that are easy to navigate. They often come with preloaded applications that can be used for a variety of tasks, such as inventory management or timekeeping.

Better asset tracking and inventory management:

Many industrial tablet models have integrated barcode scanners or RFID readers, which can be used for asset tracking or inventory management. They also often have integrated industrial sensors, such as temperature, humidity, and pressure sensors.

Multiple ports and expansion slots:

Because industrial tablets are designed for industrial use, they typically have multiple ports and expansion slots to accommodate industrial peripherals.

More-powerful processors:

Industrial tablets typically have more powerful processors than ordinary computers, making them well-suited for tasks like data collection and analysis, image processing, and video streaming.

Cellular LTE connectivity:

Industrial tablets are often used in remote industrial settings where Wi-Fi is not available, so manufacturers are equipping their devices with cellular LTE connectivity.

Better security:

As industrial tablets are being used for more critical applications, manufacturers are beefing up the security of their devices with features like hardware-based data encryption, fingerprint scanners, and device management capabilities.

Variety of form factors:

Industrial tablets come in a variety of form factors to meet the needs of different industrial applications, including handheld, vehicle-mounted, and fixed.

Cost benefits:

Industrial tablets offer a number of cost benefits over traditional industrial computers. They are typically more affordable, and have a lower total cost of ownership thanks to their longer lifespan and lower repair and maintenance costs.

Increased productivity:

Industrial tablets can help increase productivity in industrial settings by reducing downtime, simplifying complex tasks, and enabling workers to access information and applications quickly and easily.

Better decision making:

With industrial tablets, managers have access to real-time data that can be used to make informed decisions about production, inventory, and other aspects of plant operations.

Improved worker safety:

In industrial settings, worker safety is always a top priority. Industrial tablets can help improve worker safety by providing access to critical information and applications, and by enabling workers to stay connected with each other and with management.

How are industrial tablets being used?

Industrial tablets are being used in a variety of industrial applications, including:

- Automotive manufacturing: industrial tablets are being used on the factory floor for tasks such as vehicle assembly, component testing, and quality control.

- Food and beverage manufacturing: industrial tablets are being used in food and beverage production for tasks such as ingredient tracking, recipe management, and quality control.

- Pharmaceutical manufacturing: industrial tablets are being used in pharmaceutical production for tasks such as ingredient tracking, quality control, and compliance.

- Warehousing and logistics: industrial tablets are being used in warehouses and distribution centers for tasks such as inventory management, order picking, and shipping.

- Retail: industrial tablets are being used in retail stores for tasks such as price check, product information, and customer service.

- Medical: industrial tablets are being used in hospitals and clinics for tasks such as patient records, medical imaging, and prescription management.

What are the different types of industrial tablets?

Industrial tablets come in a variety of form factors to meet the needs of different industrial applications. The most common form factors are:

- Handheld: Handheld industrial tablets are small and lightweight, making them easy to carry and use with one hand. They’re typically used for tasks like data collection and inventory management.

- Vehicle-mounted: Vehicle-mounted industrial tablets are designed for use in industrial vehicles, such as forklifts and industrial trucks. They’re often used for tasks like route planning and asset tracking.

- Fixed: Fixed industrial tablets are designed for permanent installation in industrial settings. They’re often used for tasks like process monitoring and machine control.

How to choose the right industrial tablet for your needs?

When choosing an industrial tablet, you should consider the following factors:

- The type of industrial application: The type of industrial application will dictate the form factor and features you need. For example, if you’ll be using the tablet for data collection, you’ll need a model with an integrated barcode scanner.

- The industrial environment: The industrial environment will dictate the durability and ruggedness you need. For example, if you’ll be using the tablet in a dusty factory, you’ll need a model with an IP rating of at least IP54.

- Wireless connectivity: Wireless connectivity is important in industrial settings where Wi-Fi is not available. Make sure the industrial tablet you choose has cellular LTE connectivity.

- Security: As industrial tablets are being used for more critical applications, security is becoming increasingly important. Choose a model with features like hardware-based data encryption and fingerprint scanners.

Can industrial tablets be customized?

Yes, industrial tablets can be customized to meet the specific needs of your industrial application. For example, you can add a barcode scanner, RFID reader, or other peripheral to an industrial tablet. You can also choose from a variety of industrial-grade operating systems, including Windows CE and Android.

What are the trends in industrial tablets?

The industrial tablet market is growing rapidly, with new models and features being introduced on a regular basis. Some of the latest trends in industrial tablet technology include:

- The adoption of Android: Android is becoming the platform of choice for industrial tablet manufacturers. This is due to its flexibility, openness, and security.

- The rise of ruggedized models: As industrial tablets are being used in more demanding industrial environments, manufacturers are offering more ruggedized models. A ruggedized industrial tablet is a device that has been designed to withstand the harsh conditions of an industrial setting. Ruggedized tablets are often encased in a durable housing and have features like Gorilla Glass displays and MIL-STD-810G certification. MIL-STD-810G is a set of standards that are used to evaluate the durability of electronic devices. Devices that are certified to MIL-STD-810G can withstand drops, vibration, extreme temperatures, and other punishing conditions.

- The growth of industrial wearable: Industrial wearables are becoming increasingly popular in industrial settings. These devices are worn on the body and can be used for tasks like asset tracking and industrial process monitoring.

- The growth of the industrial Internet of Things: The industrial Internet of Things (IIoT) is a network of industrial devices that are connected to the Internet. The IIoT is enabling industrial tablets to be used for tasks like predictive maintenance and remote monitoring.

- More powerful processors: The industrial tablet market is being driven by the need for more powerful devices. This is particularly true in industrial settings, where tablets are being used for tasks like data collection and analysis, image processing, and video streaming. As a result, manufacturers are equipping their industrial tablets with more powerful processors, such as Intel’s Atom x86 and Core i series processors.

- LTE connectivity: Industrial tablets are often used in remote industrial settings where Wi-Fi is not available. To meet this need, manufacturers are equipping their devices with cellular LTE connectivity. This allows users to stay connected even when they’re outside of Wi-Fi range.

- Increased security: As industrial tablets are being used for more critical applications, manufacturers are beefing up the security of their devices. This includes features like hardware-based data encryption, fingerprint scanners, and device management capabilities.

- The decline of Windows: Windows is no longer the platform of choice for industrial tablet manufacturers. This is due to its high cost, lack of flexibility, and security concerns.

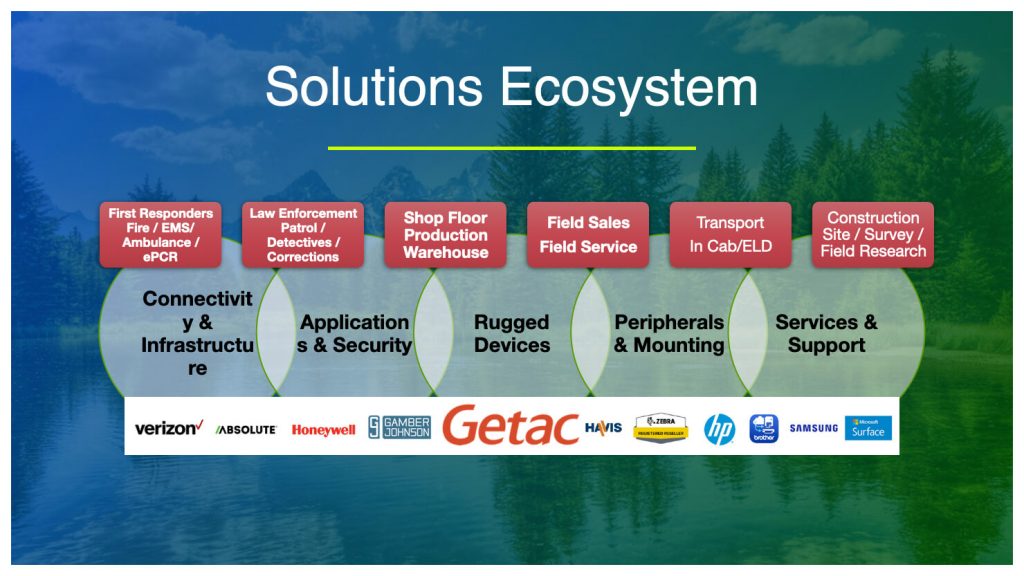

Contact our experienced team today

Affinity offers a full range of rugged industrial tablet solutions. Ranging from tactical to medical to wearable, rugged tablets go wherever you do and provide best in class battery life, widescreen displays, industry-leading security, seamless connectivity, and a comfortable grip.

Contact our experts today to learn more.